|

Enhanced

5/2-day

Central Heating Programmer

with serial computer

interface

|

|

Overview

This

project has come about from my desire to control my home heating from

work. As I have a VPN between work and home a straightforward relay

controlled from a PC would seem the easiest solution. However I also

wanted a control unit that I could operate in the house without resorting

to the computer. For example, I get up late and the heating is off,

I just want to hit a button and turn it on. In

fact the programmer shown on this page is now next to my bed so I can turn

the heating on before I get up late, and also switch

it off if I turn in early, which helps save on the fuel bills J

Features

-

Independent

control for heating and hot water.

-

10

flexible program entries.

-

Programs

can be set to operate Mon-Fri / Sat-Sun / Mon-Sun.

-

Manual

advance for water and heating

-

Water

and heating can be independently set to manual or programmed control.

-

Operation

and setup from front panel or remote serial CLI

-

Battery

backup for Real Time Clock (RTC), program settings and manual control.

-

Programmer

can be located remotely from boiler using low voltage signals over

CAT5 or 6-core alarm cable.

-

RS232

serial interface with command line interface allows full control and

setting from any computer.

-

Front

panel control can be locked-out from serial CLI

-

Based on

Microchip PIC 16F628A microcontroller

This programmer has been

designed for use with a domestic heating boiler. It provides

outputs via two relays to control the supply of Hot Water and

Heating. There are 10 program entries available and each one can

control the heating and water independently. The programmer allows manual

advance of the heating and water and disabling of program control,

useful if you're going away for a few days and want to leave the heating

and water off. As

well as providing normal front panel switch control of the heating and

water, the programmer also features a serial terminal interface that

allows it to be operated remotely

from a PC running a Terminal Emulator. The

program entries can be set to switch weekdays only, weekends only or

everyday but not individual days. I believe a programmer that can

switch weekdays or weekends is a 5/2-day programmer so I would call mine a

5/2/7 day programmer since it can do the whole week as well.

However, a 7-day programmer is one that can do individual days so I've

settled on calling mine an Enhanced 5/2-day programmer. The

programmer and boiler control relays are contained in separate units so that the relays

can be located close to the boiler while the programmer itself can be

located anywhere in the house using low voltage connections back to the

relay unit. The

connection between the programmer and relay unit requires six wires for

power, serial data and relay controls making it possible to use 6-core

alarm cable or, as I have done, operate it over the CAT5 UTP cabling

installed throughout my house. Of course it's quite simple to build

it as a single unit if that suits the application. There is also no

reason why you can't make the serial interface connection local to the

programmer in which case you only need 4 wires for power and relay

controls. If you don't

require the remote computer CLI the programmer is fully functional using

just the front panel and likewise, if the front panel isn't required, it

can be fully controlled from the serial interface and the LCD and switches

omitted from the hardware.

Software

The latest version of the

programmer

ready .HEX file is provided here.

Developed using MPLAB

V7.10

and Oshonsoft PIC

Simulator IDE.

Assembled with MPASM v04.00

The software is fully

functional and the system as described on this web page is currently

working with my domestic heating system. I've been

using prototypes since March 2005. The latest code, Version 2.0.2, has

been running since 28 May 2005. As of 25 March 2014 it's still

working and has proved to be 100% reliable.

This is the final version of

the code. I'm not going to develop it any further since the programmer now

implements all the features I want and works as I intended. I will

do maintenance code releases to fix any software related bugs / issues

reported to me.

Known issues

-

no

known critical issues.

-

Some

CLI commands allow superfluous text on the line after the

command. The command executes correctly and any superfluous text is

ignored.

-

Please

send any bug reports to

Contact us:

Functionality as designed

-

The current relay output

and manual mode settings are stored in NVRAM. In the event of a power

failure these are restored when the power resumes. If a programmed

setting should have applied at a time during the power outage, it will

not get applied when the power is restored. The saved settings that

were active at

the time of the power failure will be reapplied.

-

When

in front panel setup mode, no programmed outputs will be activated. If a programmed

setting should have applied while the programmer was in setup mode, it will

not get applied on exit.

-

On power up the

programmer sends a VT100 [ESC] c command to the terminal to reset it.

This may cause extraneous characters to be displayed or other issues on a non VT100

emulator.

-

Time

is displayed / entered in 24 hour format only.

-

Serial interface

operates at 9600bps, 8 bits, 1 stop, No parity. Baud rate is not

configurable

-

When

in front panel setup mode the serial CLI is disabled.

Code

Revisions

V2.0.3

V2.0.2

-

Enabled

the PIC Watch Dog Time (WDT) and added supporting code.

-

New

command 'dw' shows number of Watch Dog timeouts that have occurred

since power-up. These should not occur if the programmer is

functioning correctly, if they do this alerts you to a potential

problem.

-

Implemented

front panel setup functions. Allows time to be set. Program entries to

be viewed, cleared, entered and edited.

-

Changed

handling of serial CLI input buffer overflow. The behavior is now

consistent with handling of unknown commands.

-

The

CLI 'p' command now shows output control for Hot Water followed by

Central Heating. This is the opposite way round to firmware before

V2.0.0

V1.9.1

-

Added

CLI command to enable / disable front panel control. This has been

added to allow the front panel to be locked out when using automated

control of the unit from the CLI. It also provides a way to stop

my girlfriend from turning the heating on all the time:-)

-

CLI

relay control command letter has been changed from 't' to 'u'.

-

The

relay control and manual mode CLI commands worked by inverting the

current setting. This has now changed so that the setting for

on/off or manual/programmed is explicitly specified on the command

line.

-

Moved

the on/off text for heating and water on the LCD to the extreme ends

of the display. This is to allow the display of the text 'Locked' when

the front panel is disabled.

V1.9

-

Prior

to FW V1.9 the LCD display had the text CH- and -HW on the second line

but as the programmer is now cased and the front panel artwork has

legends on it, this text has been removed from the V1.9 code.

-

The manual mode status was indicated with the characters 'm' and 'p'.

This has now been replaced by the text 'Man' and 'Prg'

-

Added

CLI function to send a VT100 [ESC] c command to the terminal to reset

it.

-

Send

VT100 [ESC] c command to the terminal at power-up.

-

Added

command to return an ASCII hex byte with the current status of the

relay outputs and manual mode settings. For use with automated control

of the CLI.

-

Improved

the CLI 'p' command entry format and parsing.

-

Made

program control for CH and HW outputs fully independent by adding a

no-change flag and enabling this feature within all related functions.

Hardware The

hardware for the programmer comprises two units. The first contains the

two relays

that switch the mains power to control the boiler. This also has an RJ45 socket

to allow connection into a CAT5 cabling system that takes power, serial data

and relay control input signals to the second unit, an intelligent programmer. There is also a 2.1mm DC power socket that is used to

connect an external 9~12V DC power adapter. This supplies power to the

relay board and the programmer controller. A 9-pin 'D' socket

provides connectivity to a PC serial interface.

The

programmer unit is based on a PIC16F628A micro controller. The programmer

front panel has a 2x16 line LCD display that shows the time

and programmer status, with switches for manually overriding the

programmer. A serial interface for connection to a computer running a

terminal emulator allows complete control and programming of the unit

remotely. A Dallas DS1307 Real Time Clock (RTC) is used for time keeping and storing the program time

settings in its NVRAM. When power to the programmer is removed, the

RTC uses a 3V lithium coin cell to maintain the time, date and NVRAM data.

The

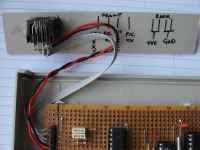

programmer control unit itself only draws about 10~15mA from the power supply. The current for the relays is

additional to this and the LCD used in the programmer is not

back-lit. The relays I used operate from 12V and draw ~30mA when

on. The 12V power supply for the whole setup as described only needs

to provide about 100mA. In practice something capable of supplying 500mA

would be better. The exact specification of the relays and LCD panel

used should also to taken into consideration when specifying the PSU. The

78L05 regulator IC shown on the schematic is not capable of

supplying power to an LCD panel with LED backlight.

The

schematic diagram of the programmer is shown below, click on the image for

large copy. Construction details can be

found in the next section.

|

Programmer schematic (click to enlarge)

Schematic in PDF format

|

Final assembled

version and a development prototype. |

During development I used

the serial interface driver shown here

rather than the MAX202CPE device. This circuit is very cheap to

construct and works quite reliably from a PC. However, it does derive its

negative 12 volt supply in a parasitic fashion from the serial transmit

line of the host device. Therefore the host must drive its TxData line

with RS232 signal levels. If you don't want the expense of the specialized

driver chip and know what you want to connect to, this makes a cheap

alternative. To make

the final circuit more compliant and function reliably with any serial

device I made a decision to use the MAX202CPE line driver. A number of

manufacturers produce similar pin-compatible devices to the Maxim part

that could be used here.

I'm using the

programmer with the relays located at the end of about 10M

of CAT5 UTP cable. Although the PIC is driving the line, internal

protection diodes on the port pin will pass any spikes onto the power

rail. The 120 ohm resistor / 1nF capacitor on each

relay control output are there to slow rise and fall times on the output

and also filter any transient noise on the line from reaching the output

pins

of the PIC. The

display is a standard 2 x 16 LCD and the code is written for the HD44780

controller command set. The

relay outputs from the programmer were designed to connect to a logic level

relay interface and will not drive relays directly. I

used a 2-channel relay board kit from Quasar Electronics. Kit

No 3156. (This is made by

DIY

Electronics, their kit K156

which is resold by various

other

companies)

As I'm using the

programmer with the relay kit above I can say that the two work reliably

together. In principal there is no reason why you can't construct

your own relay driver. The one

shown in this schematic should

also work with 12volt relay coils.

The BC548 transistor shown can be replaced with any general purpose NPN

transistor. You will need to take into account the current drawn by

the relays and ensure that;

-

The transistor is

capable of sinking the current drawn by the relay coil.

Small PCB mount relays with a 12V coil will typically draw about 35mA

and the BC548 can sink 100mA continuous max.

-

If you use 5volt relays

remember that the 78L05 voltage regulator can only supply 100mA

maximum and that both relays may be energized at the same time. You

will therefore almost certainly need to use a 7805 1Amp regulator in place of the 78L05.

-

The relays used will need to

be specified according to the specific boiler being controlled, but

typically, for use in the UK a relay rated for 240V mains operation and 3A

contacts would be suitable.

-

If you locate the relays

remotely from the programmer as described here, you must locate the

relay driver circuit with the relays. Don't put the relay

driver on the programmer circuit board and then switch the current to

the relay coils through several metres of cable.

** This project involves

the control of mains voltages. If you are not confident about

working with high voltages or don't understand about wiring this into your

existing heating system you should employ the services of a qualified

electrician. You should also ensure you comply with any local

regulations with respect to the installation of the programmer **

Datasheets

Construction

The

following description of the construction is based on the unit I've built

myself which includes the front panel display and controls. The programmer

doesn't actually need the front panel interface. The software will

function correctly with or without the front panel interface components

installed,

so if you want to control it from the serial interface only, you can omit

the LCD display and 10K contrast preset, switches Sw1 thru Sw5 and diodes

D1 thru D5. You must keep the 10K pull-up resistor to pin 4 (RA4) of the

PIC. You could also use it with the LCD display but without

the switches.

| The

main programmer unit is housed in a 130 x 95 x 30mm ABS case. (See

Rapid Electronics part # 30-3892 by Evatron) The LCD

display panel and five push button switches are mounted in the top half of

the case. When mounting the switches the top of the buttons should

be just proud of the top of the case, this makes them

easier to operate once the front panel overlay is fitted. The

switches have then been fixed using hot-melt glue.

The ribbon cable to the LCD panel was fitted and then LCD glued into the

case, again using hot-melt glue. Once all the

cables to the top of the case were fitted some hot-melt glue was used to secure them and

provide strain relief . The use of hot-glue does make

it difficult to replace or repair parts in the future but not impossible.

Since it's a one off project I was happy with the ease of construction and

felt this outweighed maintainability.

An

RJ45 socket was removed from a Network Interface Card and used for

the external connections. A

cut out was carefully made in one of the end panels. This was then

attached using hot-melt glue and the cabling attached afterwards.

Keeping the cut-out an interference fit with the RJ45 socket helps keep it

nice and solid when assembled. |

|

The

main control board was fitted in the bottom half of the case and secured

with a couple of small dabs of hot melt glue. The moulded mounting pillars in the bottom of the case where shaped to hold the

board mechanically so only the smallest amounts of glue where needed to

secure it. This was done intentionally so that it will be easy to remove

the board.

| The central heating boiler

in my home is located in the garage next to the data comms'

cabinet. There's a standard commercial heating programmer that was

installed with the

heating system and I have wired my control box in parallel with

this. When my programmer is operating, the commercial programmer

is set to manual off. This means I can easily revert back to

using the commercial programmer if needed.

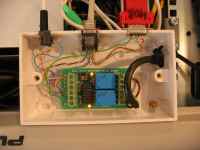

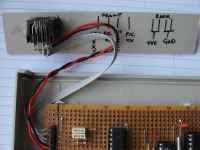

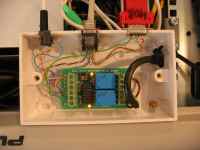

A 40mm deep double gang surface mount box has been used to

mount the relay control board and connectors. Slots have been cut

into one side of the box to take a 2.1mm DC power socket, RJ45 socket and

9-pin 'D' connector. The three wires from the boiler are brought in through a hole in one end of the box and secured with cable

ties. The relay control box is located in the bottom of the comms'

cabinet which allows it to hook up to the PC (also located in the

cabinet), the CAT5 cabling patch panel and power from a small 12volt

/ 500mA plug-top adapter.

I have a small PC in the bottom of

the cabinet that functions as a file server and systems controller

for the house, so this was the logical system to connect the serial

interface to. A terminal emulator runs on the PC and this is

accessed via a remote desktop application.

|

Relay control box with the cover removed.

|

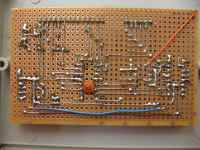

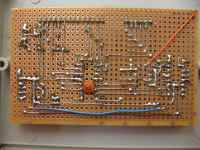

The main programmer has been constructed on double sided matrix board and a

detailed construction layout is provided below. Construction is

fairly straightforward and should be done in conjunction with the

schematic diagram provided in the hardware section above.

Circuit

construction notes:

-

The 10Kohm resistors are

1/8 watt devices and somewhat smaller than standard 1/4 watt carbon

film types. You can use 1/4 watt resistor but you will need to mount

them vertically if you follow this layout.

-

The 47nF capacitor

shown on the schematic diagram decoupling the power rail to the

16F628A has been soldered on the reverse side of

the board directly across the Vss-Vdd pins of the PIC. See

Photo

-

The oscillator pins of

the DS1307 RTC device have been bent out horizontally from the

package, the narrow ends of the pins cut off and the crystal soldered

directly to the stubs on the IC. I've done it this way because it's

difficult to meet the layout requirements for the crystal circuit as

detailed in the datasheet for the device without using a PCB.

Done the way I've shown the RTC clock should run very

accurately.

-

The battery holder used

was a surface mount type, tacked to the copper pads on the top side of

the board. After

construction visually inspect the connection between the +VE terminal of

the battery holder and pin 3 of the DS1307 socket to ensure there are no shorts to ground or anything

else.

-

Once

the board has been assembled, apply power to the board before

inserting the three IC's or connecting the LCD. Ensure that 5volts appears at the IC sockets

power pin positions and the LCD header. Correct any problems.

-

Adjust

the LCD contrast preset so pin 3 of the LCD header plug is at 0v.

-

After

the power supply has been tested install the three IC's and connect

the serial interface to a PC running a terminal emulator

application. The programmer will function for testing purposes

without the LCD or switches connected so you can check the basic

functions through the serial CLI interface and then connect the LCD

and switches once you've established the basic operation of the

circuit is okay.

-

With

the LCD connected, adjust the contrast preset resistor until the

display can be read.

-

Switch functions

Sw1 - HW on/off

Sw2 - CH on/off

Sw3 - HW manual

Sw4 - CH manual

Sw5 - 'Setup' button

pad board construction layout

|

Assembled board

|

Reverse side of board

|

Detail of battery holder

and 32Khz crystal |

Assembled programmer

|

RJ45 socket detail

|

Although I installed

connector pins for attaching the LCD display, keypad and RJ45 socket, I

ended up soldering the connecting cables directly to the board, mainly

because I didn't have the necessary sockets and also because once

assembled it isn't likely to be opened up again.

Front panel artwork

| Artwork for the front

panel was produced using Microsoft Visio. This was then

printed onto photo quality glossy paper. Once the ink was dry (make

sure it is or you'll be doing it again) the area where the LCD

panel locates was carefully removed and the whole artwork cut out

from the A4 sheet.

This was then laminated using a

normal office document laminator. The only thing I did before

laminating was to work out where the switches would be and then cut

out rectangles in the second layer of the laminating sheet.

This reduces the stiffness of the completed panel and makes the

operation of the switches underneath more tactile. |

|

Once this was done I used some

fine sandpaper to rough up the surface of the case and the back of the laminated

artwork. DO NOT sandpaper the LCD screen or the window in the laminate

sheet, in other words do it carefully. Once the surfaces were prepared and

cleaned off, the laminate was stuck to the case using a cyanoacrylate glue (Superglue)

Operation

When

the programmer powers-up it displays the firmware version on the LCD

display for 2 seconds. It then checks two validation bytes in

the RTC NVRAM. If these do not contain the correct validation data the

LCD will display RTC Initialized for 7 seconds, other wise it displays RTC

ok for 2 seconds.

In normal operation, the LCD display shows

the status of the CH

and HW outputs, manual mode status and the day and time. A separator

':' between the hours and minutes on the display blinks every

second.

Photo right: Programmer

with FW Rev 1.8

Photo far right: Programmer with FW Rev 1.9

|

|

The front panel of the programmer

can be used to turn the Central Heating (CH) and Hot Water (HW) boiler controls

on or off independently using the buttons located either side of the LCD

panel. The status of each output is displayed on the LCD.

There are also two buttons to

toggle the CH and HW operation between program controlled and manual. In

manual mode, program settings are ignored. The manual mode status is shown on

the top row of the LCD with 'Man' for manual and 'Prg' for program. When operating in

manual mode the heating and hot water can still be turned on and off using the front panel or from

the serial interface.

If the LCD displays the word

'Locked' on line 2, then the front panel switches have been disabled from the

serial CLI. The unit can still be controlled from the CLI and the LCD continues

to display time and status. The front panel can only be re-enabled from

the CLI.

For details of operating the programmer, follow the links below

Front

Panel Setup Operation

CLI

operation

Disclaimer

|